Data management in industrial services using an innovative Excel add-in

Challenge In the dynamic world of industrial services, the efficient management and processing of data represents a constant challenge

Im Technologiepark 12, 26129 Oldenburg

Challenge In the dynamic world of industrial services, the efficient management and processing of data represents a constant challenge

There is no excerpt because this is a protected post.

Our project example describes the successful implementation of an IoT project in which we developed a turnkey solution for a customer to transfer and visualize 3000 data points from 15 OPC servers to an IoT database. We explain the challenges our client had when integrating many different devices and data sources and how we overcame them with our solution. We use mostly proven and secure open source software to store, visualize and transform data and to create tailor-made applications. Our blog describes the process we used to implement the IoT project, from analyzing the requirements to training the customer's employees. The result was a successful project that offers the customer a growing database and creates the basis for further evaluations.

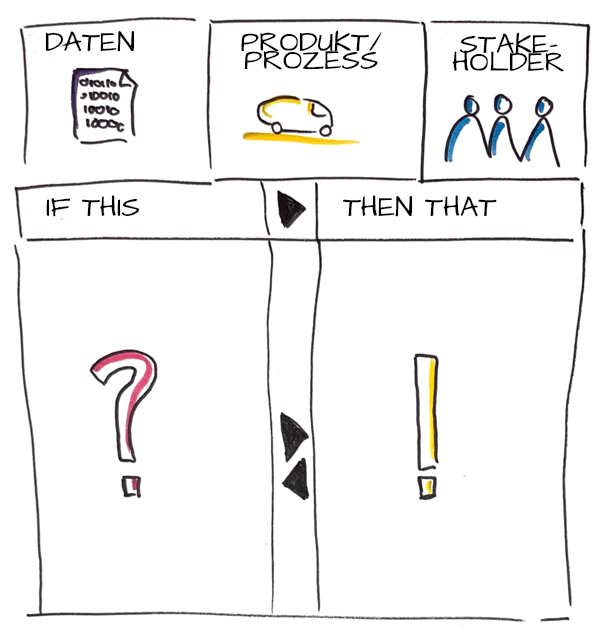

The challenge of determining the use case of IoT The Internet of Things is characterized by the technical connection of devices and systems

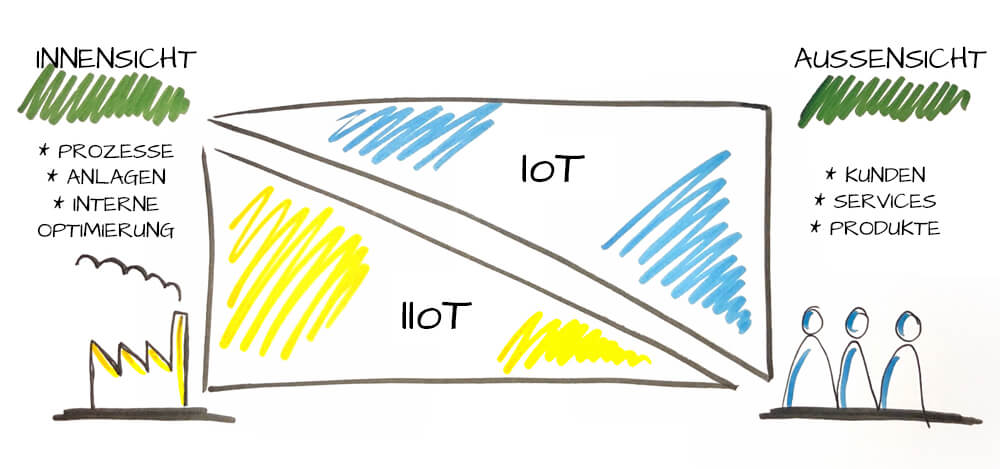

If you deal with the topic of digitization, you will currently encounter two extremes: On the one hand, there are general ones

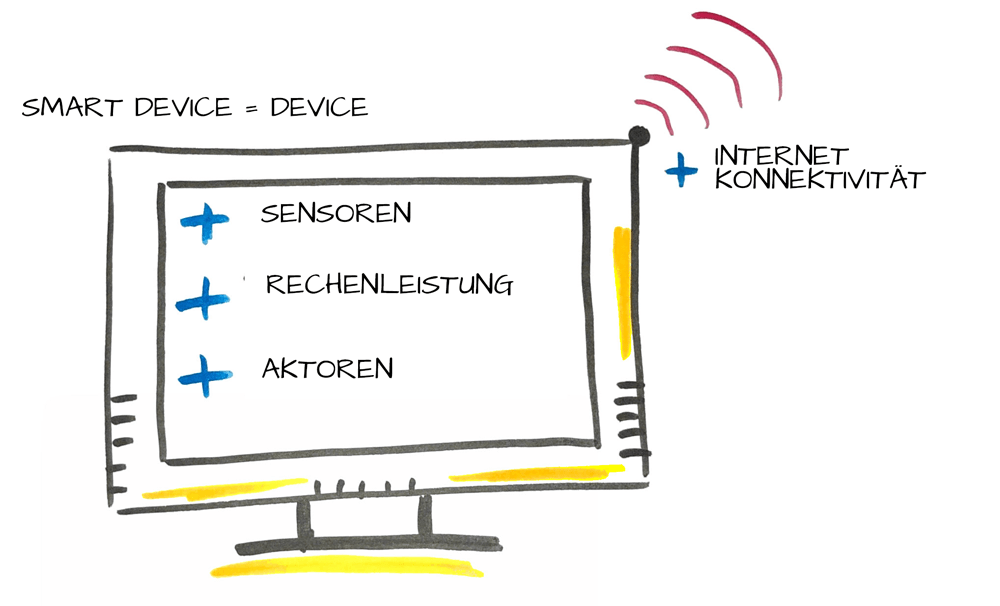

The Internet of Things (IoT for short) means the ability to network all kinds of devices. Through

The term Internet of Things describes the connection of systems, devices and everyday things to the Internet. The term

The management and controlling of our customer - a medium-sized company active in industrial services - uses Microsoft Excel for planning,

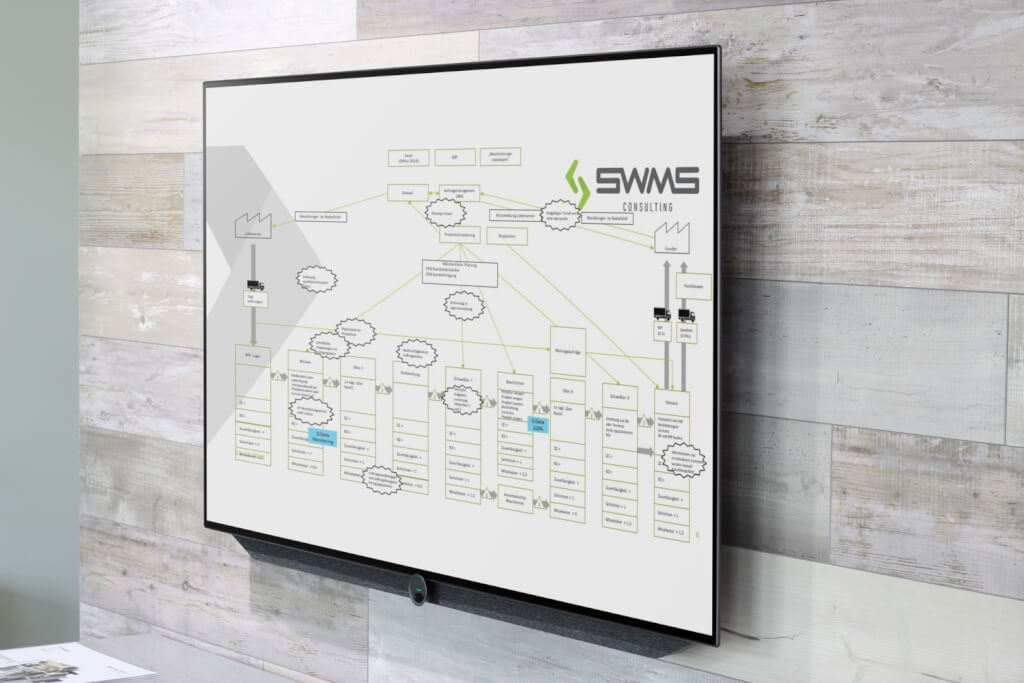

The system developed for production data acquisition and order management replaces the manual control of orders with production based on paper-based order documents. The low-code system enables individual applications in a short time and offers starting points for further digitization projects. The use of operating data represents the basis for increasing potential in production.

The company has dealt with the question of how the manufacturing processes can be better supported and optimized by IT systems. Together with SWMS, an order management system was developed that orchestrates modern IT technologies and makes the manufacturing processes more transparent, efficient and error-free. The system is future-proof and flexibly adaptable.